Welcome to Soman Group

- +91 9321224033

- 022 241315795

- response@somangrp.com

Welcome to Soman Group

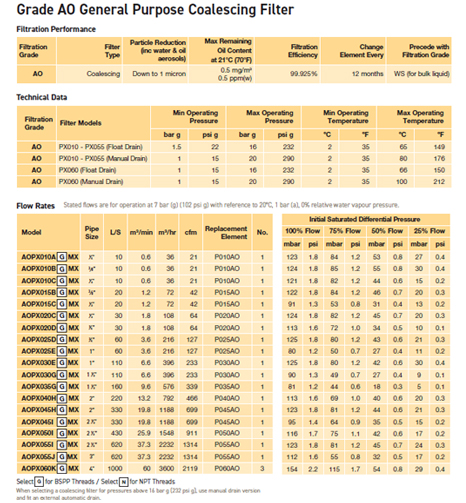

Coalescing Filters (OIL-X Grades AO & AA)

Coalescing filters are probably the single most important items of purification equipment in a compressed air system. They are designed to not only remove aerosols (droplets) of oil and water using mechanical filtration techniques, but to remove solid particulate to very low levels (as small as 0.01 micron in size).

Installed in pairs, the first compressed air filter is a ‘general purpose filter’ which protects the second ‘high efficiency filter’ from bulk contamination.

Dry Particulate Filters (OIL-X Grades AO & AA)

Dry particulate filters provide identical particulate removal performance to the equivalent grade coalescing filter. Relying on mechanical filtration techniques, high efficiency dry particulate filters can provide particle reduction down to 0.01 micron with a removal efficiency of 99.9999%. When coupled with a Pressure Dewpoint ≤-40°C, to inhibit and control the growth of micro-organisms, they can provide significant reduction of microbiological contaminants.

Adsorption (activated carbon) Filters (OIL-X Grades ACS & OVR)

Oil vapour is oil in a gaseous form and will pass through a coalescing filter just as easily as the compressed air. Oil vapour removal filters provide a large bed of activated carbon adsorbent for the effective removal of oil vapour, providing a high level of protection against oil contamination.